I like to keep my readers on the edge of their seats… so buckle up: this Ferrari 296 LMGT3 played me a delicious trick I didn’t see coming.

After my work on the Mercedes-AMG LMGT3, I thought all GT3 cars would fall within similar ranges in terms of force feedback. And yet, the Ferrari completely shattered my expectations. Where the Mercedes gave me a p99 of around 24.4 Nm, the 296 shot up much higher. Needless to say, I couldn’t just carry over my AMG settings and apply them to the Ferrari: I had to start over and understand why this car generated such a different force feedback signature.

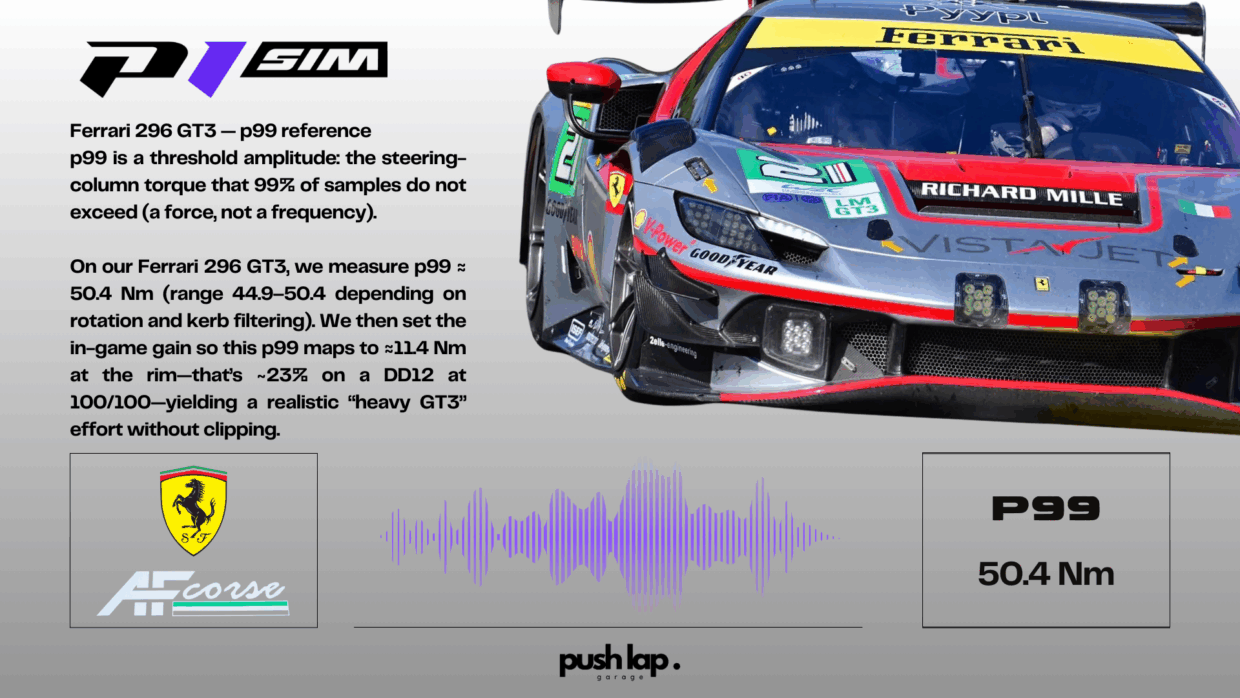

The shock of the p99 (50.4 Nm)

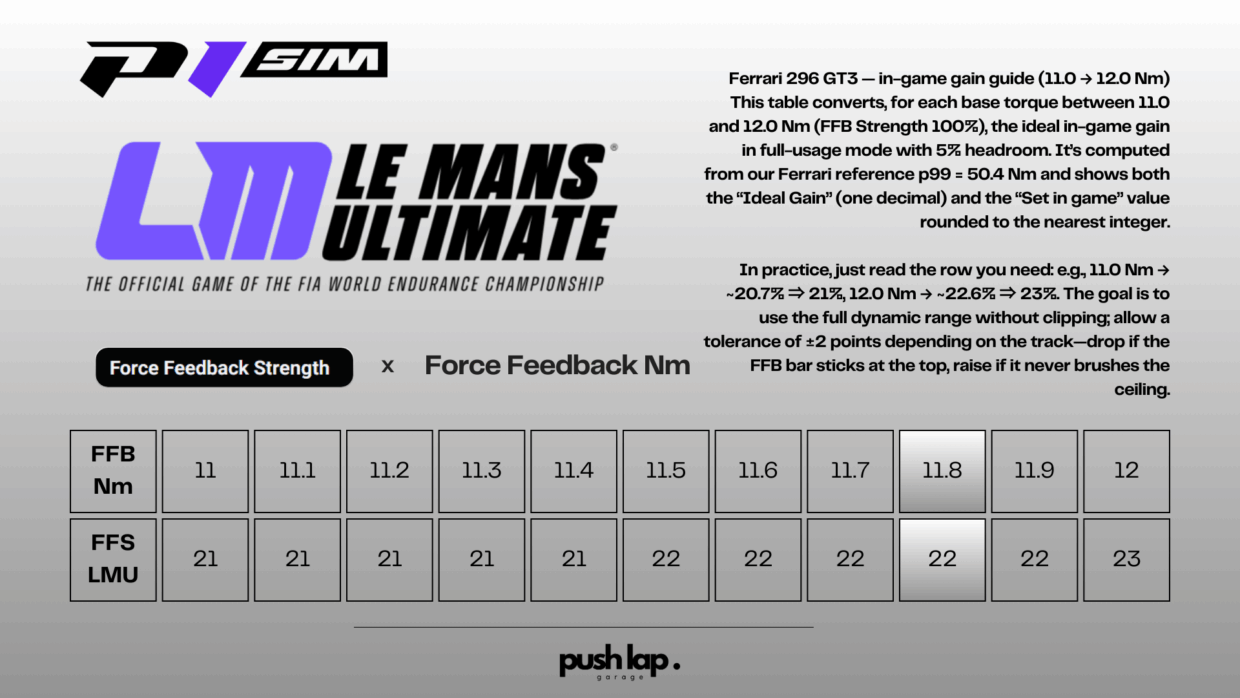

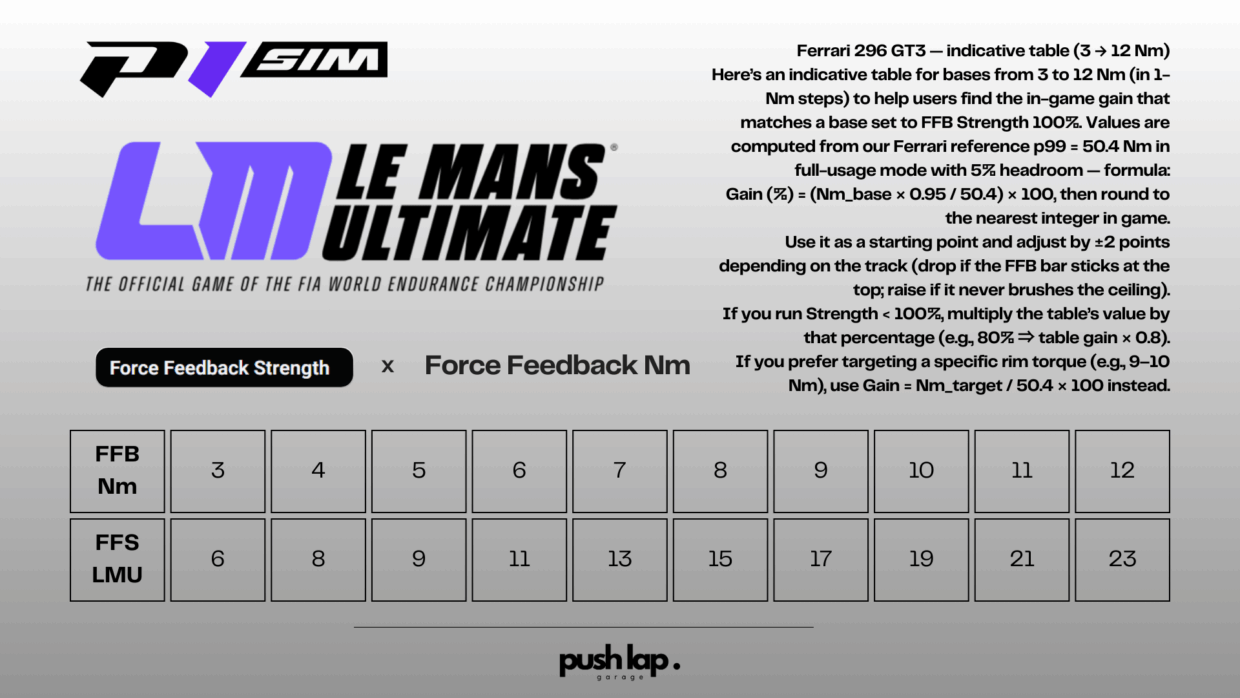

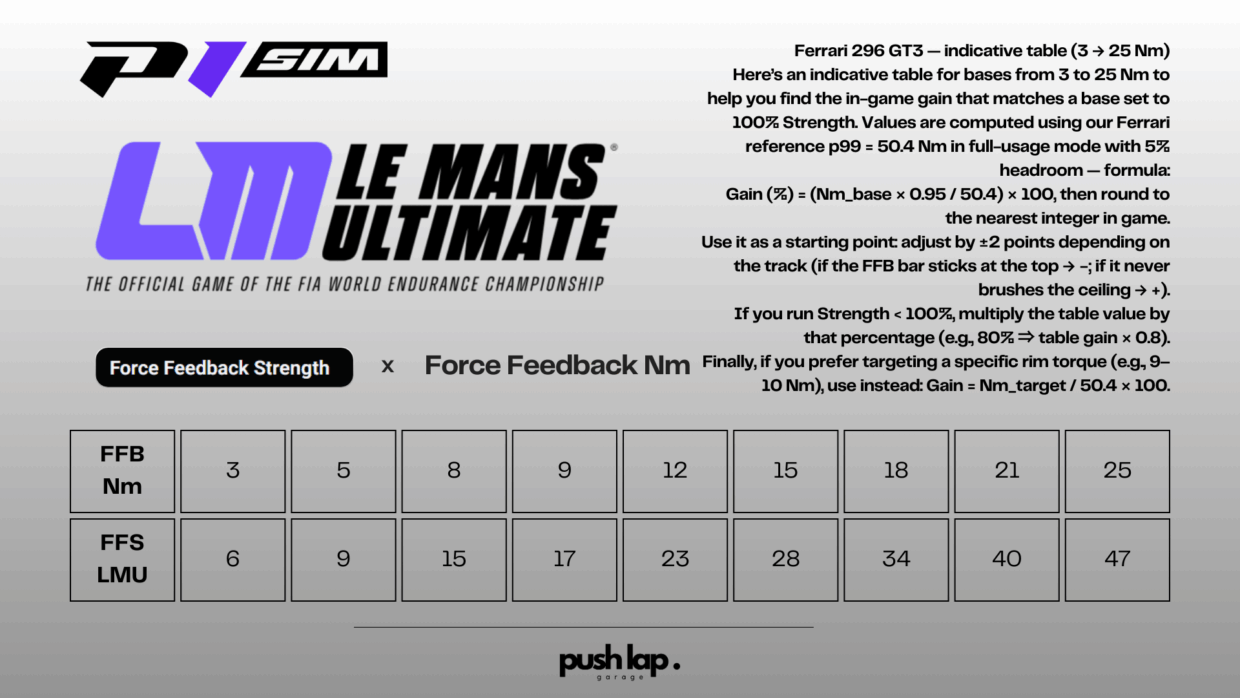

Direct consequence: to avoid clipping and losing detail, I lower the in-game gain. On a 12 Nm base at 100 % (Strength 100 %, FFB 100 %), the optimal gain is ≈ 23 % (calculation: 12 × 0.95 / 50.4 ≈ 22.6 %).

This setting aligns the base’s usable range with the Ferrari’s dynamics while preserving headroom for peaks. Even better: if I want to lighten steering effort without losing fidelity (e.g., target 10 Nm at p99), I simply reduce Strength to ~88 % (10 / (0.95 × 12)) while keeping gain at 23 %.

The information curve remains identical — only the scale of effort changes.

Table “Ferrari 296 – p99 = 50.4” (base 100 %, indicative gain)

(Adjust by ±2 points depending on bumps/kerbs.)

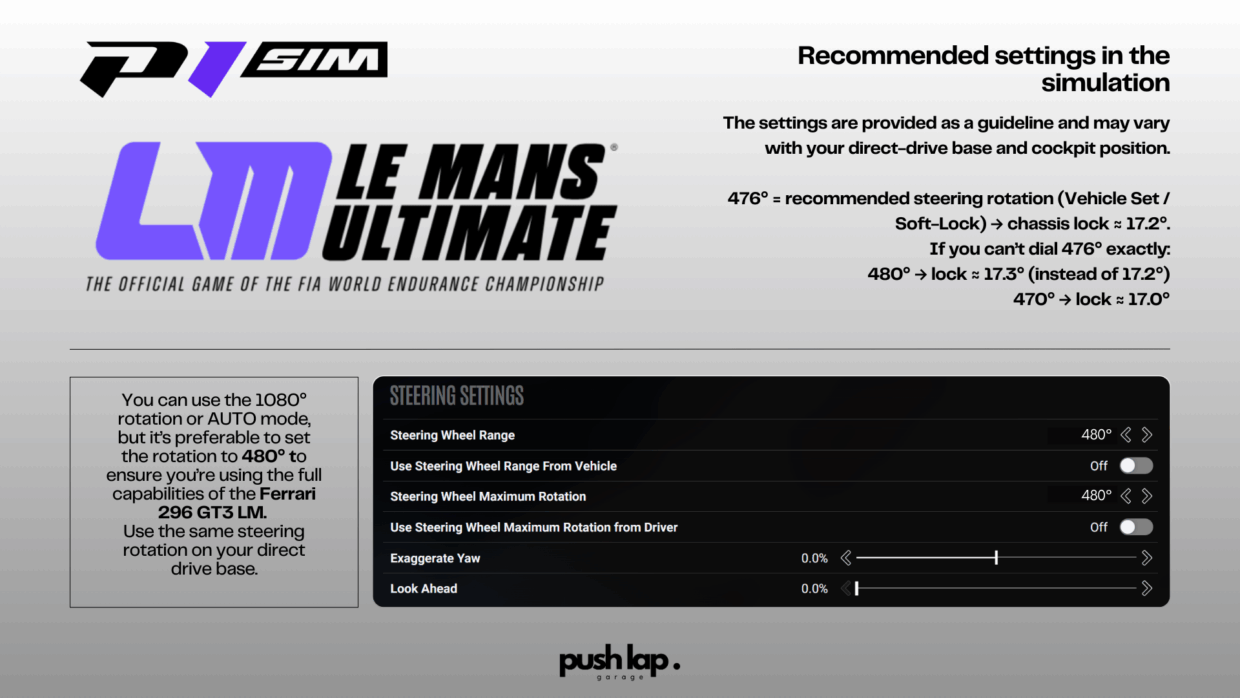

Rotation: why 480° is crucial !

On the Ferrari, analysis shows a steering column p99 ≈ 50.4 Nm measured at COTA with a car rotation of 476–480°.

This high torque requires that the hand → wheel amplitude be perfectly matched to the 296’s steering geometry: that’s exactly what 480° everywhere ensures.

Technically, rotation isn’t just a comfort setting: it’s the neuromuscular leverage ratio linking hand input (δ_hand) to wheel angle (δ_wheel).

Too much rotation (e.g., 900–1080°) stretches δ_hand → lowers dδ/dt, artificially smooths transients, and dilutes self-aligning torque; you think you’re driving cleanly but you’re really “steering on a spring.”

Too little (e.g., 420–450°) compresses δ_hand → over-excites SAT, creates oscillations, and pushes you into over-correcting — sure way to add noise into telemetry (and tires).

Around 480°, you get a practical steering ratio where a small wrist input corresponds to a useful wheel angle change (~16–17° per side, depending on geometry), which stabilizes the hand/FFB relationship and makes the p99 measurement reliable.

In practice:

– 480° = the only rotation coherent with the 296’s physics → no artificial SteerAngle clipping in telemetry → clean p99.

– With a 12 Nm base at 100 % (Strength 100 %, FFB 100 %), gain ≈ 23 % to fully exploit the base without clipping.

– If you target 10 Nm at p99, keep 23 % gain and set Strength ≈ 88 % → same information density, lighter effort.

– At 480°, the Ferrari retains its natural agility while leaving enough correction margin during oversteer phases.

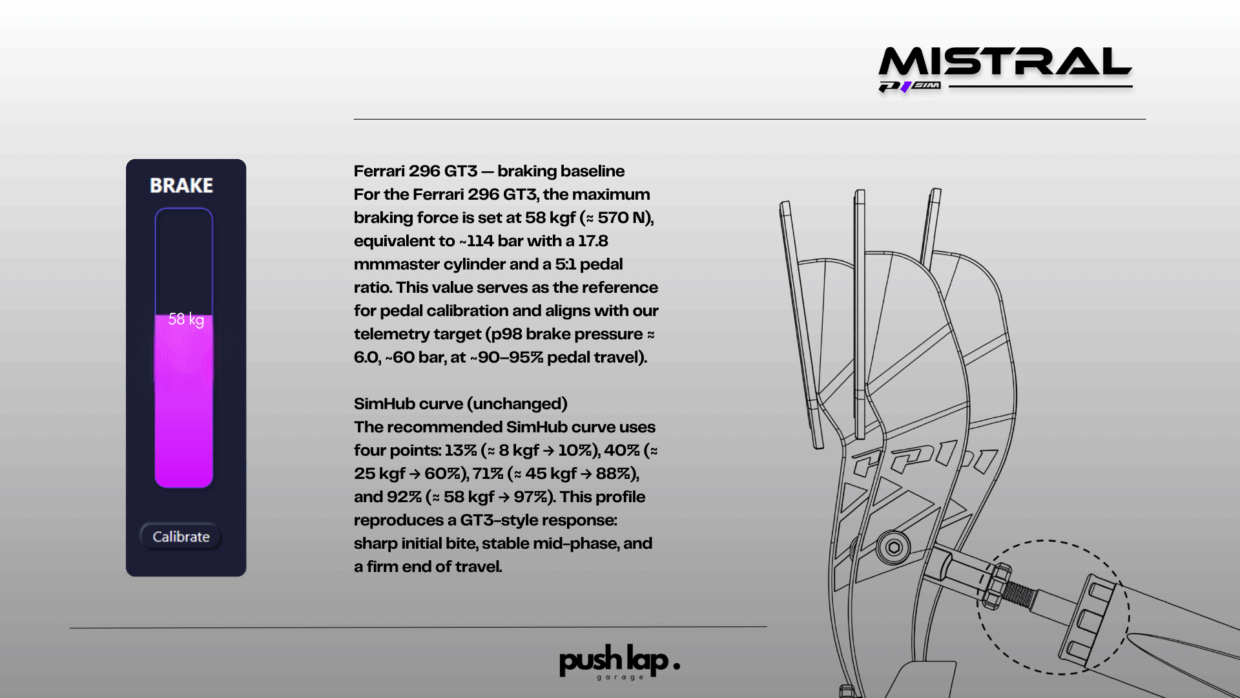

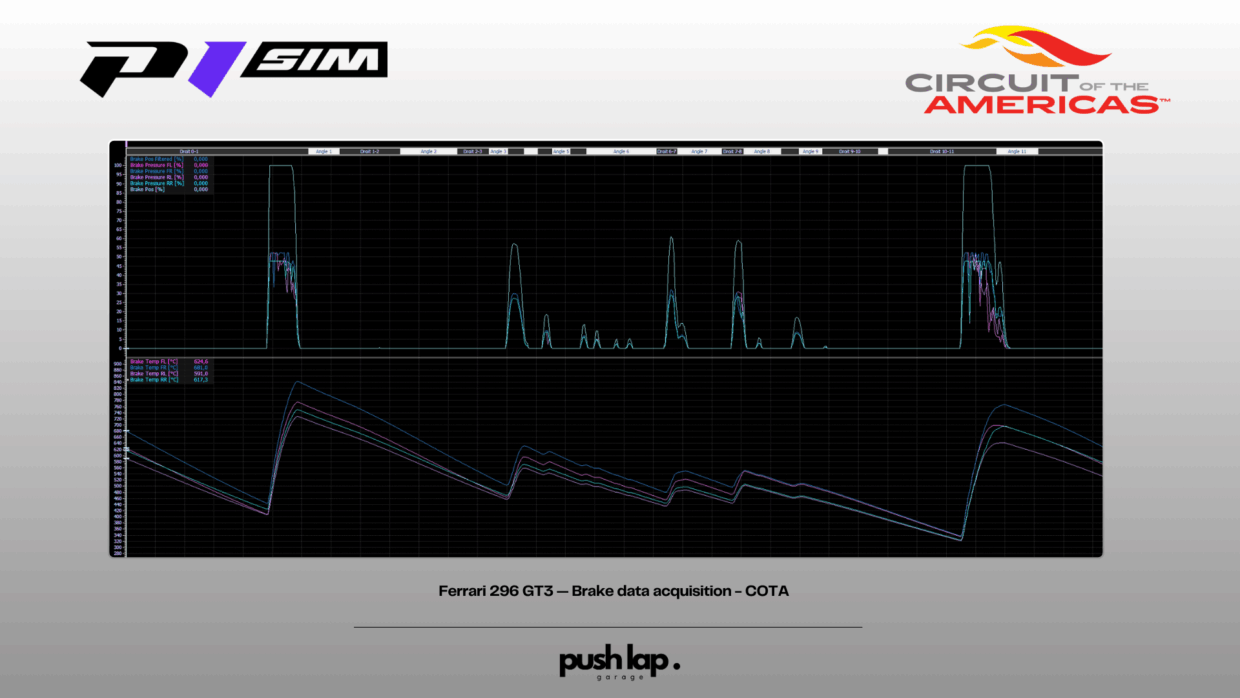

Braking: why 58 kgf became my reference !

Braking was the other major discovery. Using the P1 SIM Mistral pedal set, I was able to precisely quantify pedal pressure.

After many trials cross-checked in MoTeC, one number kept coming back consistently: 58 kgf peak. This isn’t superstition — it’s applied physics.

Calculation chain

58 kgf ≈ 569 N at the foot. With a 5:1 pedal lever ratio and 0.9 mechanical efficiency, that produces ~2,560 N at the master cylinder.

With a Ø 17.8 mm piston, the hydraulic section is ~2.49×10⁻⁴ m², resulting in a circuit pressure of ~103 bar.

This is precisely where the 296 delivers maximum deceleration without prematurely triggering ABS. Below this, braking lacks bite and costs meters.

Above it, ABS activates too soon, “straightening” the car on entry and killing the Ferrari’s incisiveness.

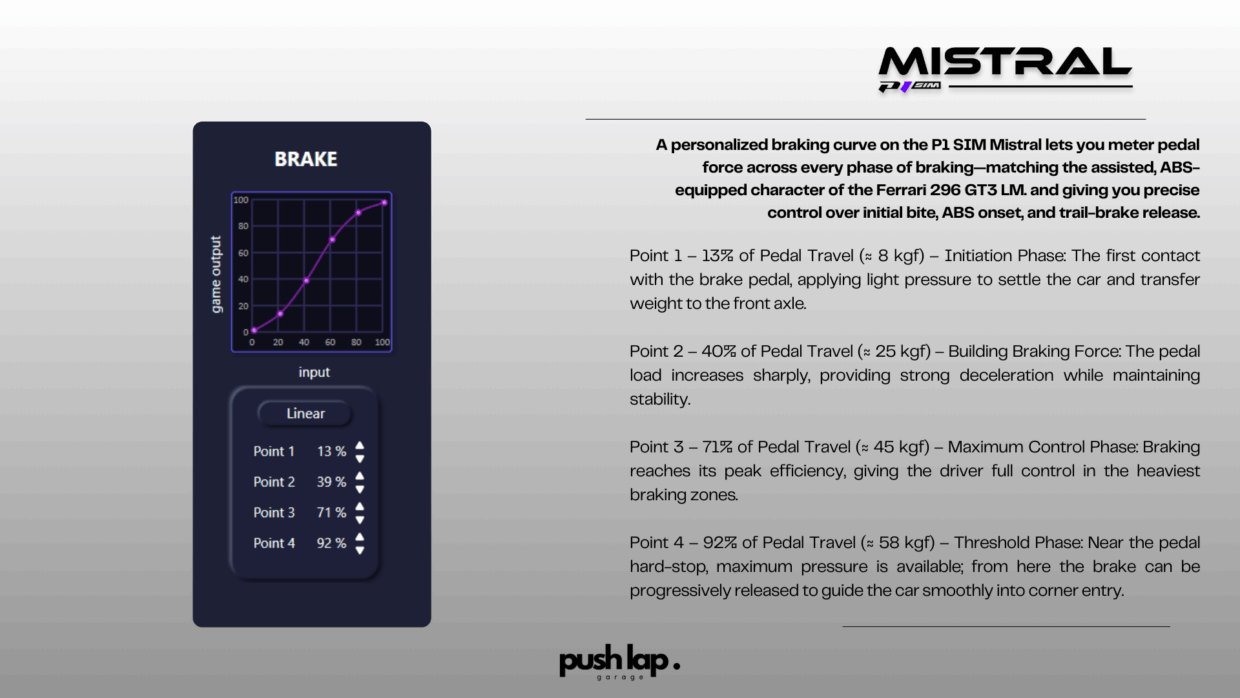

4-point brake curve (Mistral)

To exploit this window, I designed a 4-point brake curve tailored to the 296, with an extended mid-zone for trail-braking:

• 13 % (~8 kgf): initiate transfer without planting the nose.

• 39 % (~24–25 kgf): strong but controlled decel, margin before ABS.

• 71 % (~45 kgf): the golden zone for rotation control.

• 92 % (~58–60 kgf): peak, reserved for heavy straight-line braking.

On bumpy tracks, I lower the 4th point to 88 % to prevent ABS noise.

Elastomers: sculpting the brake pedal

One of the most decisive yet underestimated parts of the P1 SIM Mistral pedals are the elastomers.

These FIBRO cylinders aren’t just comfort parts: they define both the progressivity of travel (dF/dx) and the final resistance needed to hit target pressure.

For the 296 LMGT3, the sweet spot runs from SOFT to VERY HARD elastomers: a soft initial zoneto smoothly load the front, then a firm, progressive end-stop to stabilize pressure around 58 kgf without hitting a wall.

All-hard setups make modulation too abrupt; all-soft setups collapse and ruin repeatability.

The strength of the Mistral lies in mixed stacking (soft → medium → hard), reproducing the hydraulic bite, pressure build-up, and finally the rock-solid firmness of a hot endurance caliper.

The benefit is MoTeC repeatability: peak value and ramp-up slope become predictable run after run, locking in the 58 kgf / 4-point method.

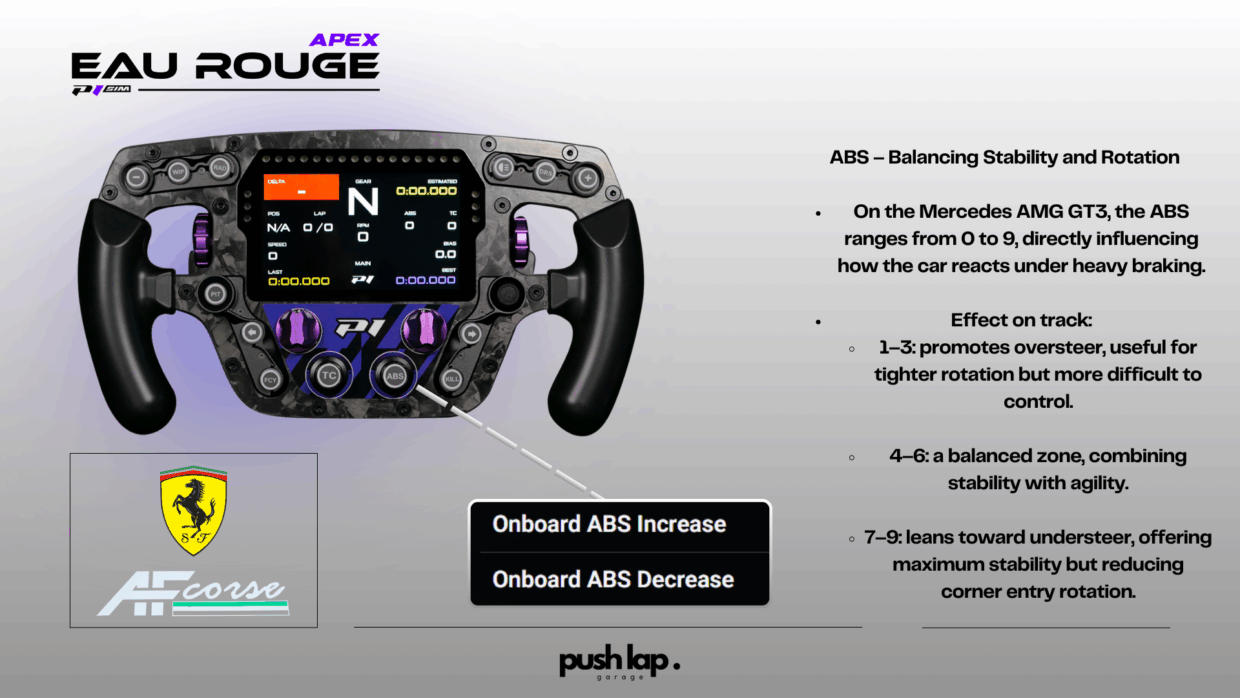

ABS: finding the sweet spot between stability and rotation

The 296 LMGT3’s ABS runs from 0 to 9, each value shifting chassis balance under braking.

• 1–3: late intervention → more rear freedom → sharper rotation, but more instability (a “qualifying” setup).

• 4–6: the golden zone — enough intervention to stabilize, while keeping agility alive. My race stints were mostly at 5, occasionally 6 on hot tracks/long runs.

• 7–9: safest, but tends toward understeer on entry. Useful in degraded grip, rain, or very long stints, but costly in lap time.

ABS here isn’t just a safety net: it’s a dynamic tuning lever sliding the Ferrari between scalpel and armored stability.

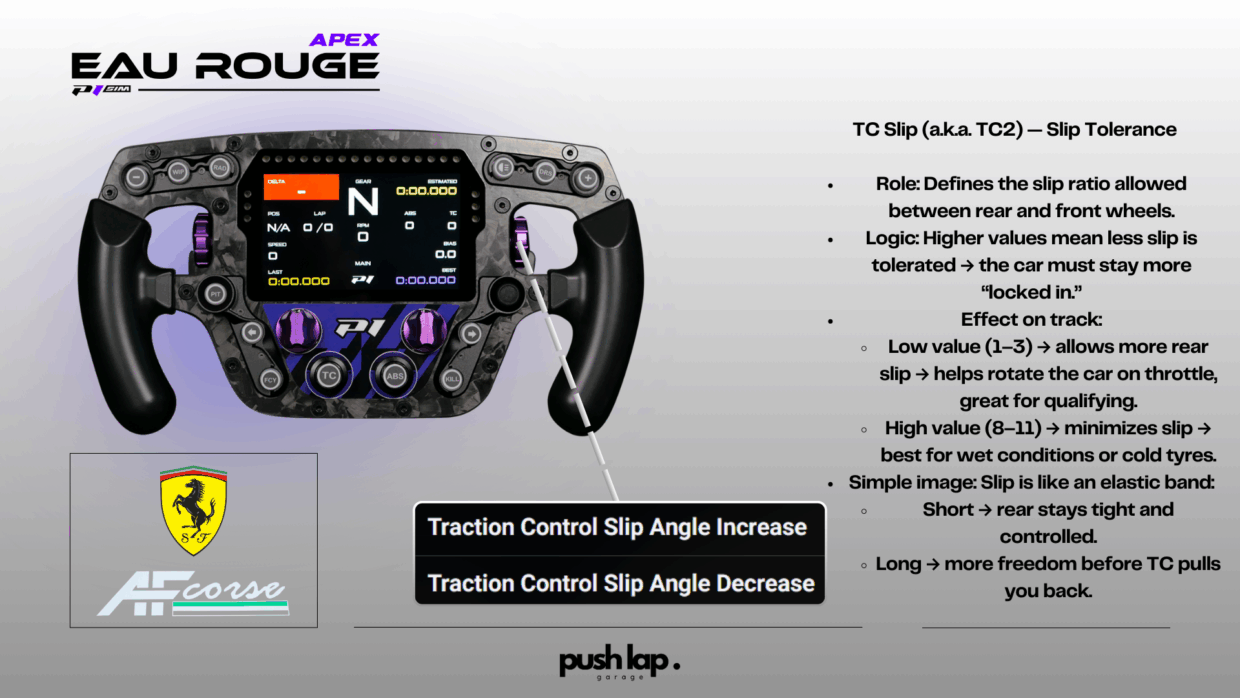

Traction Control — three levers to tame the power

The 296 comes with a three-layer TC system, each parameter addressing a different part of wheel slip control.

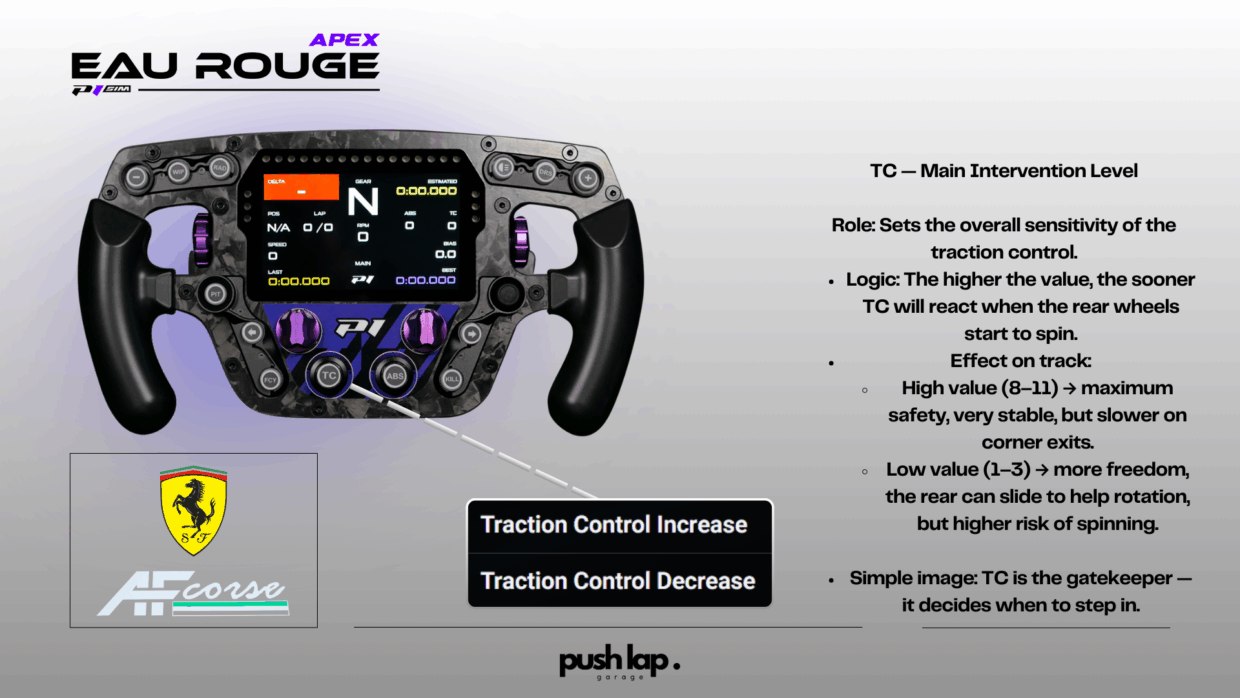

TC — Main Intervention Level

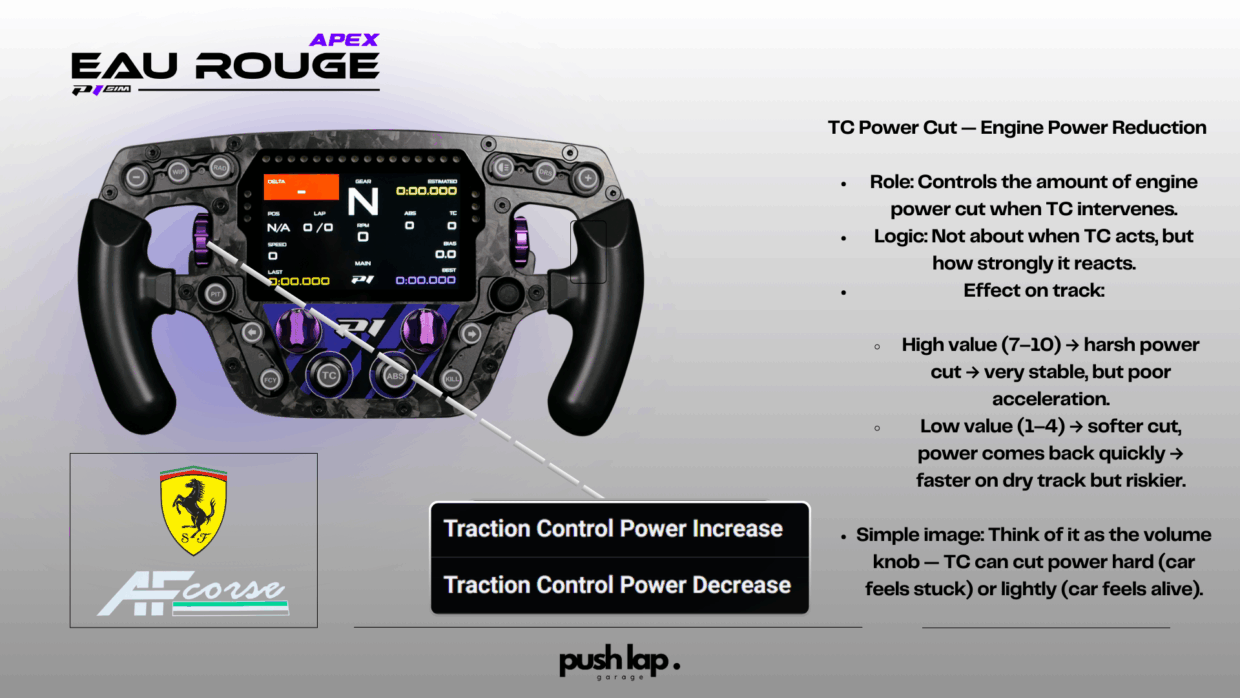

TC Power Cut — Intensity of engine cut

TC Slip (TC2) — Slip tolerance

Think of it as a trio: TC Main decides when to act, Power Cut sets how strong, Slip defines how long the rear can dance before being reeled in. Balanced well, the Ferrari adapts seamlessly from one-lap attacks to endurance consistency.

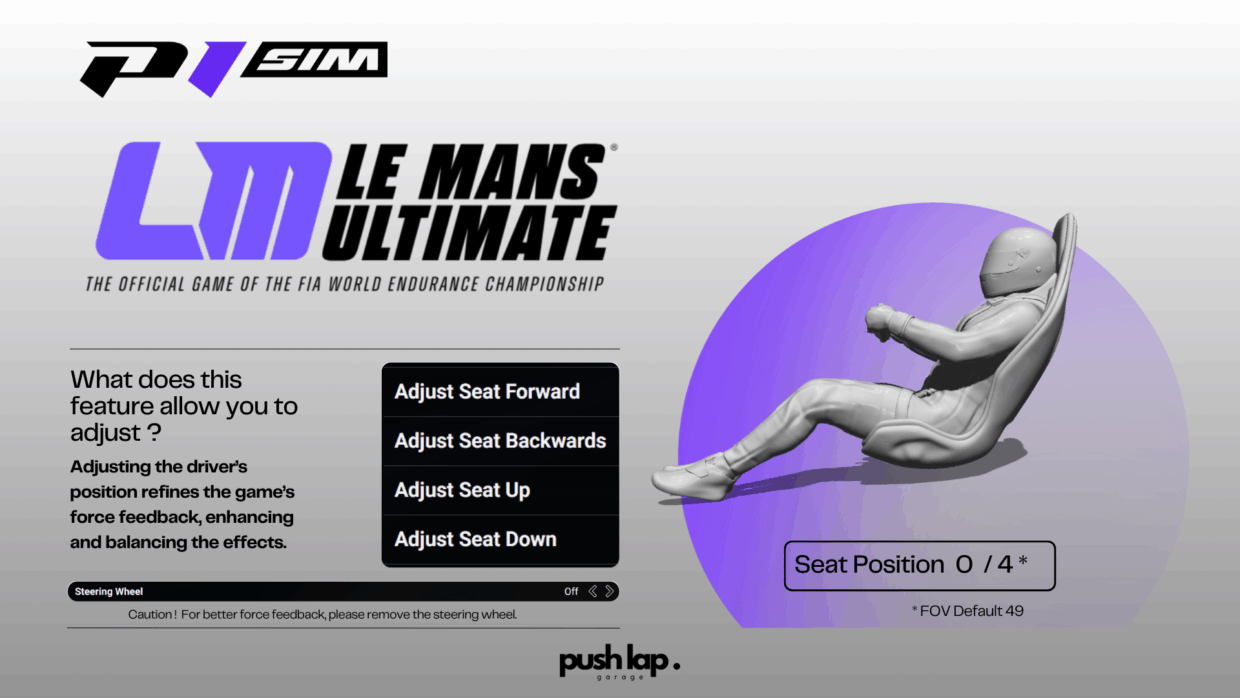

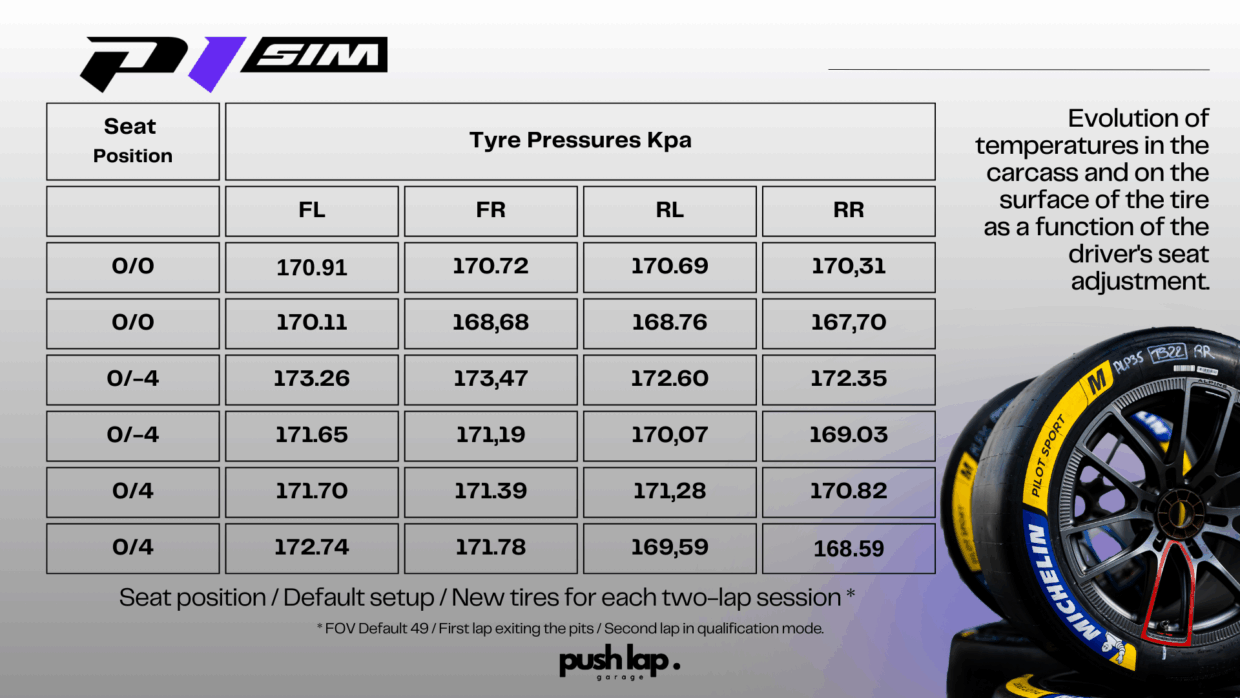

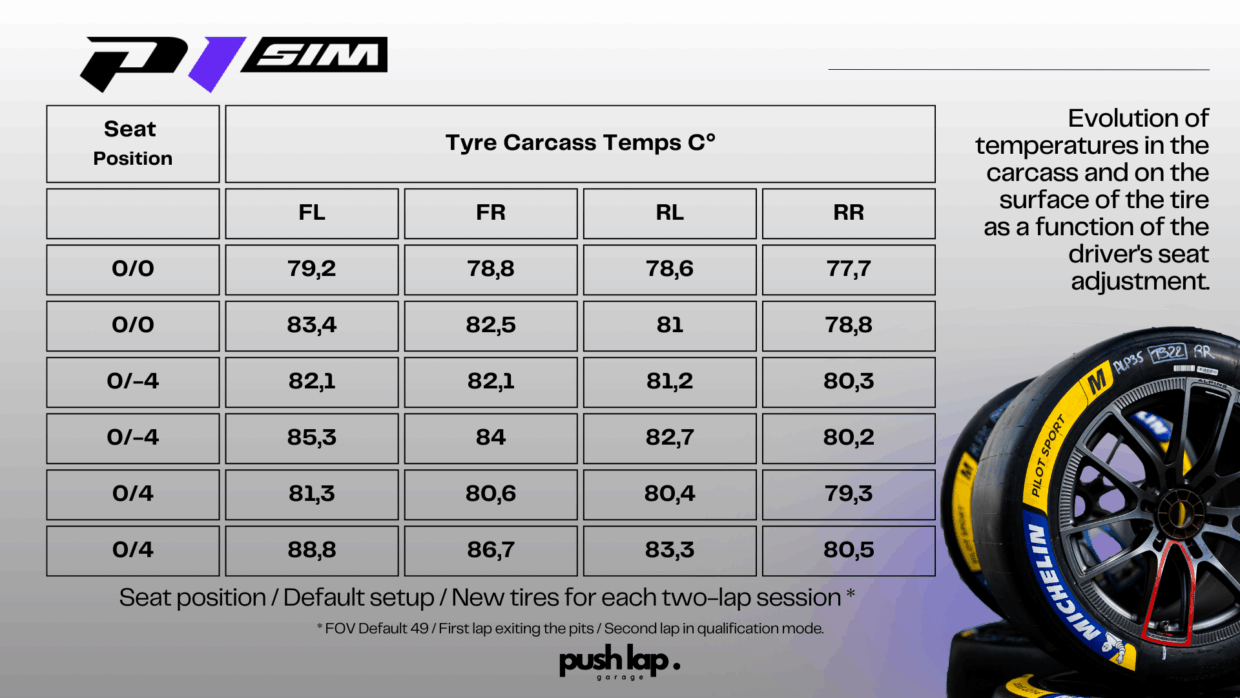

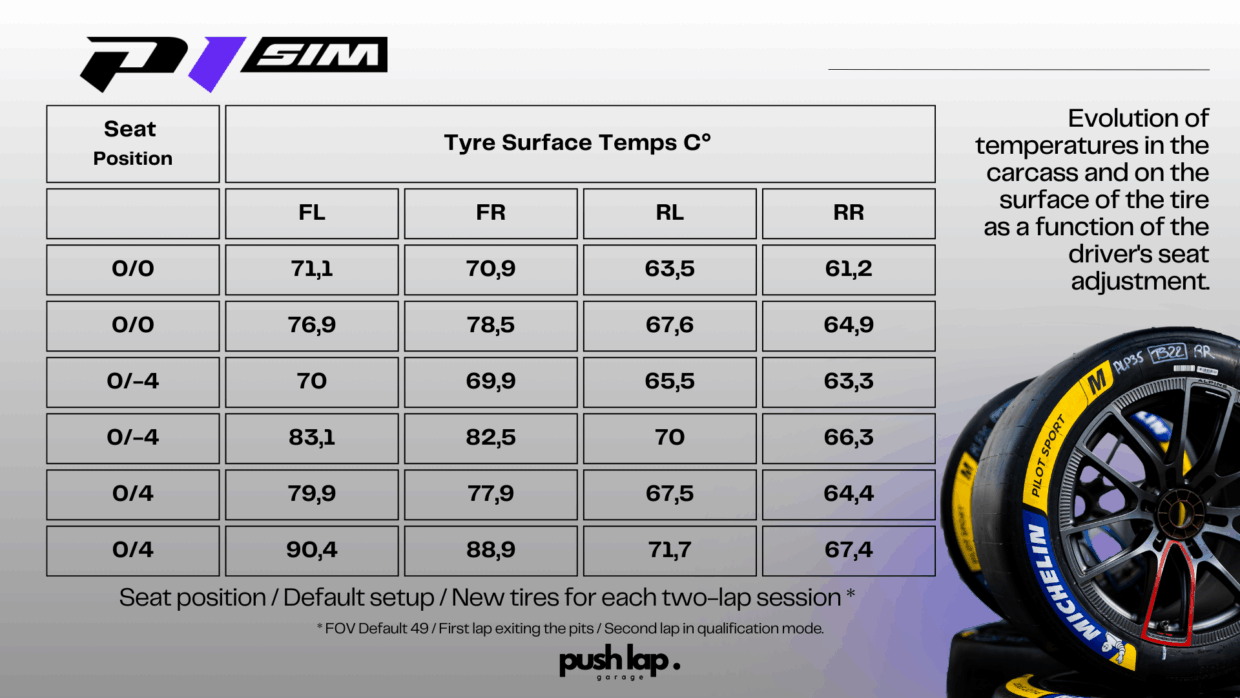

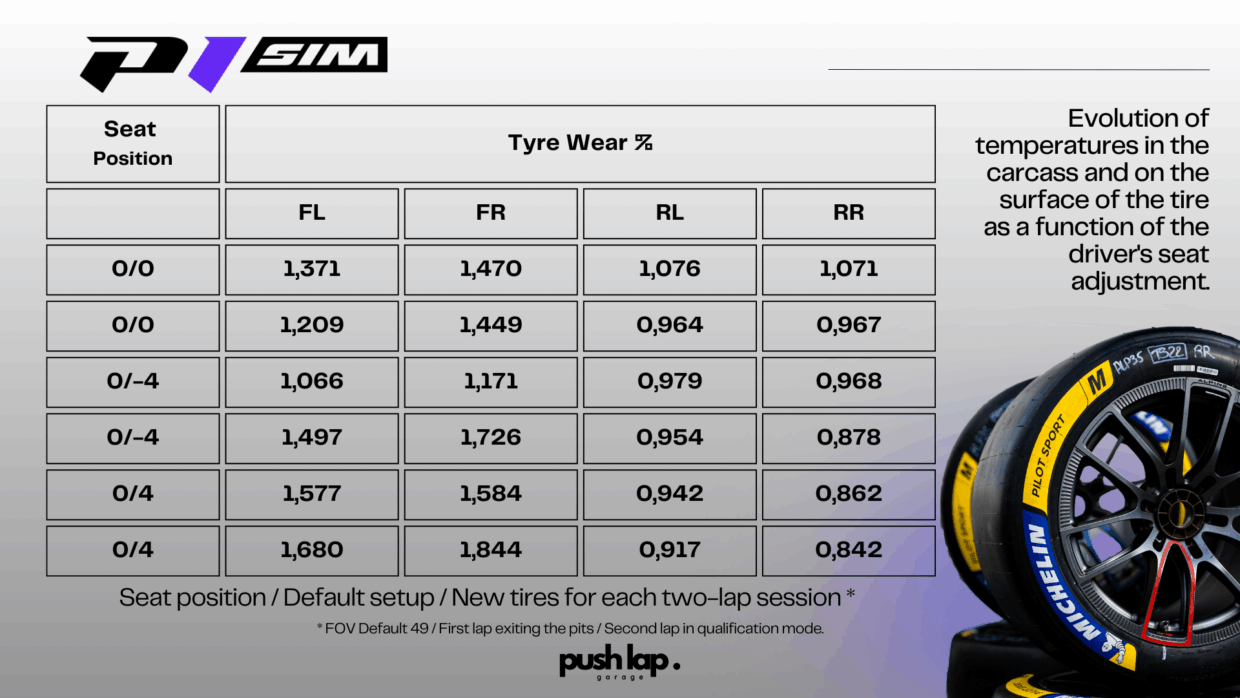

Driver position: why the tires “talk” better

Moving the seat 0 and +4 upward sharpened my perception of weight transfer.

No, it doesn’t change the physics; it changes me: my perceived FOV, my timing, my precision on brake release.

Positioned slightly above and forward of the front axle, I “held” the Ferrari better in its slip-angle window, stopped over-correcting, and the wheel calmed down. The tires confirmed it.

Four tables to illustrate

Pressures: more symmetrical hot rise AV/AR.

Carcass temps: reduced drift over 3–5 laps.

Surface temps: lower peaks mid-corner (less parasitic slip).

Wear: tighter Δ L/R and Δ F/R — signature of controlled slip vs torn rubber.

Not cosmetic: it’s quality of driving feeding directly back into tire life.

Conclusion: P1 SIM Mistral consistency, two ways to approach LMU, and what’s next

If I can dig this deep, it’s because of the P1 SIM Mistral pedal set. Its rigidity, mechanical repeatability, and sensor stability give me Newton-level consistency in MoTeC.

Without that reliability, I couldn’t peg a 58 kgf peak and see it again run after run; I couldn’t build 4-point curves that behave exactly as drawn. The Mistral turns sensations into data, and data into method.

Ultimately, Le Mans Ultimate can be approached in two ways. The classic way: let auto-settings run and just drive.

Or the research way: push the sim to its limits, calibrate FFB on p99 = 50.4, lock rotation at 480°, map braking to 58 kgf, adjust driver position to 4/3, then check it all against tire tables. It’s slower to set up, but it’s coherent, reproducible, performant.

The logical next step? Study the tarmacs. Each asphalt changes tire excitation, heat build-up, and how SAT feeds back through the column. We’ll refine calibrations per surface to lock in robust references (gain, 4-points, 4/3) per grip type.

Because in LMU as in the real world, every detail counts — and that’s how you turn a wheel that “makes forces” into a measuring instrument.

Leave a Comment