A Logical Continuation of Our Research

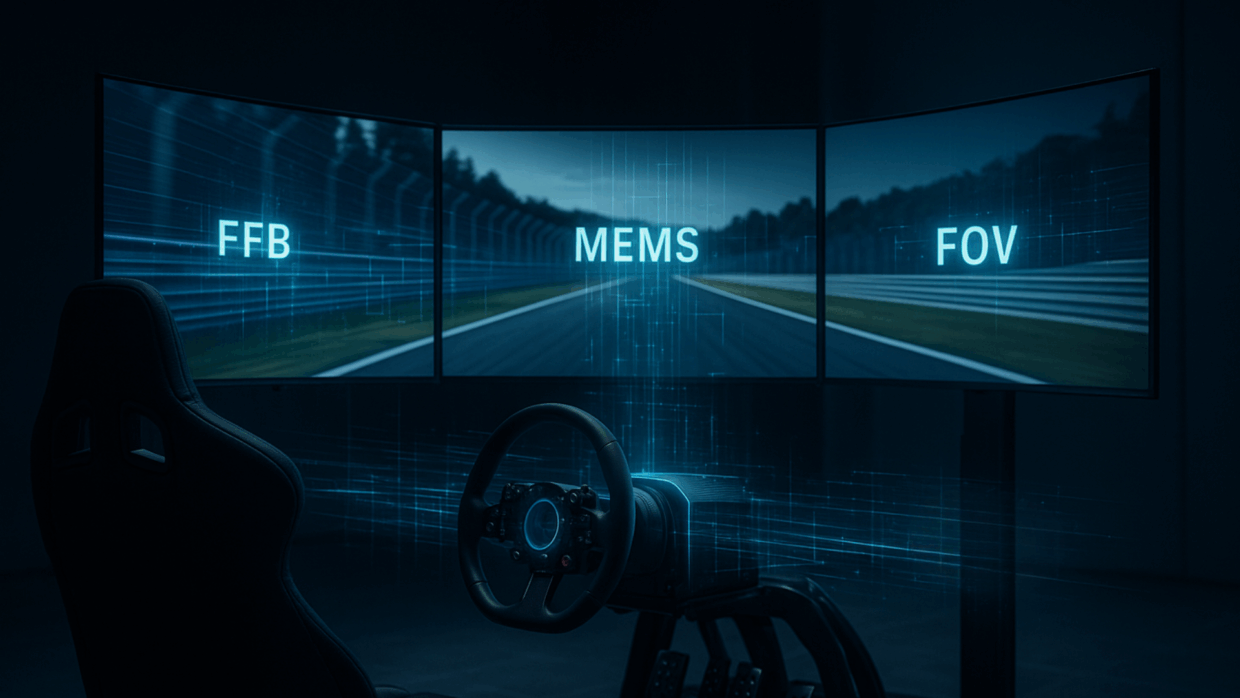

In our previous article on MEMS sensors and their potential role in the coherence of Force Feedback, we outlined a simple but ambitious hypothesis: what if the alignment between the physical data measured by these sensors and the virtual driver’s visual position (through Field of View, or FOV) directly conditioned the way we perceive forces on the steering wheel?

Since then, our research has gone deeper with the introduction of a new measurement tool: the p99 torque, a statistical metric that isolates the physical “signature” of a car in a simulation. By logging telemetry with MoTeC, we verified something essential: the physical data transmitted by the simulation engine remains consistent and stable—even when the steering feel changes dramatically.

In other words, the issue is not instability in the physics engine, but rather a mismatch between the reference frame used by the simulation and the way our brain interprets it through cockpit view and FOV. This article is therefore a major update, enriching the MEMS ↔ FOV hypothesis with concrete data from p99 and offering a new perspective on the mismatch between physics and perception.

MEMS Sensors: The Invisible Reference of Physics Engines

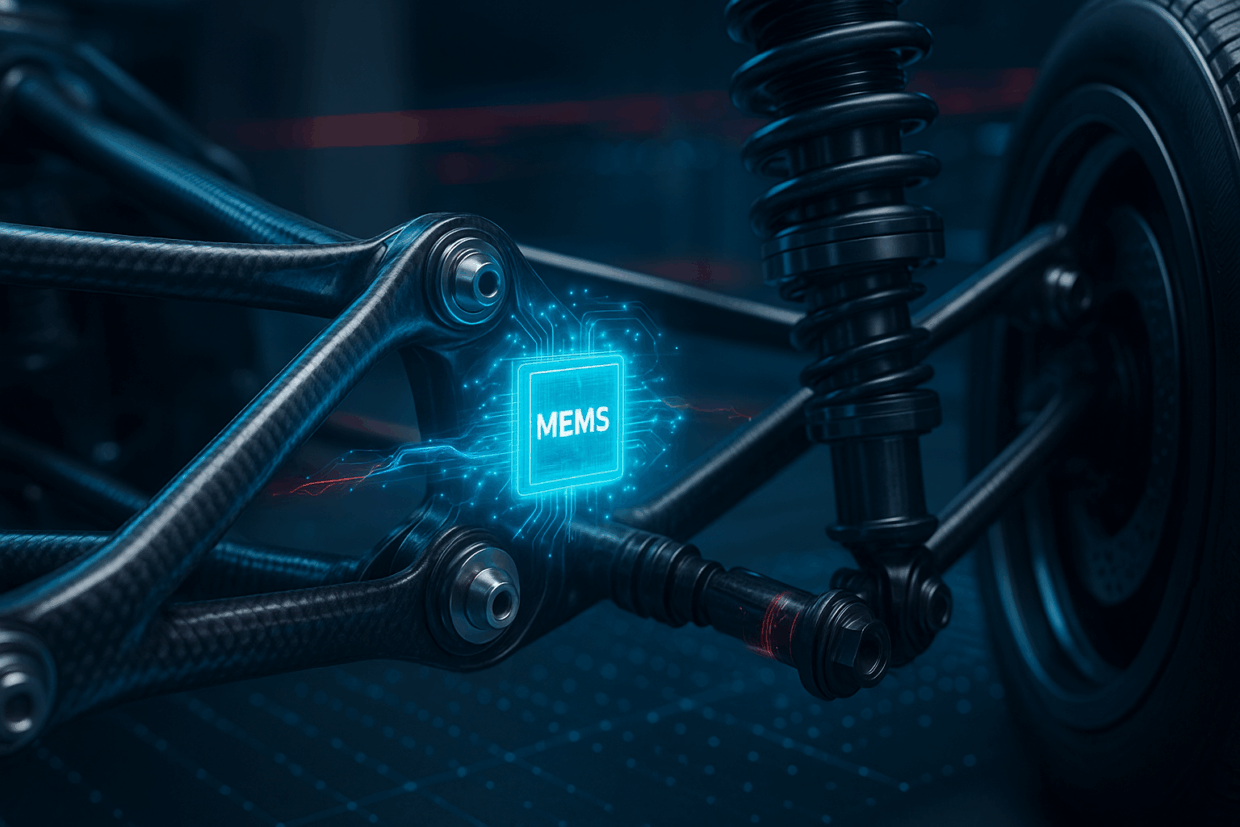

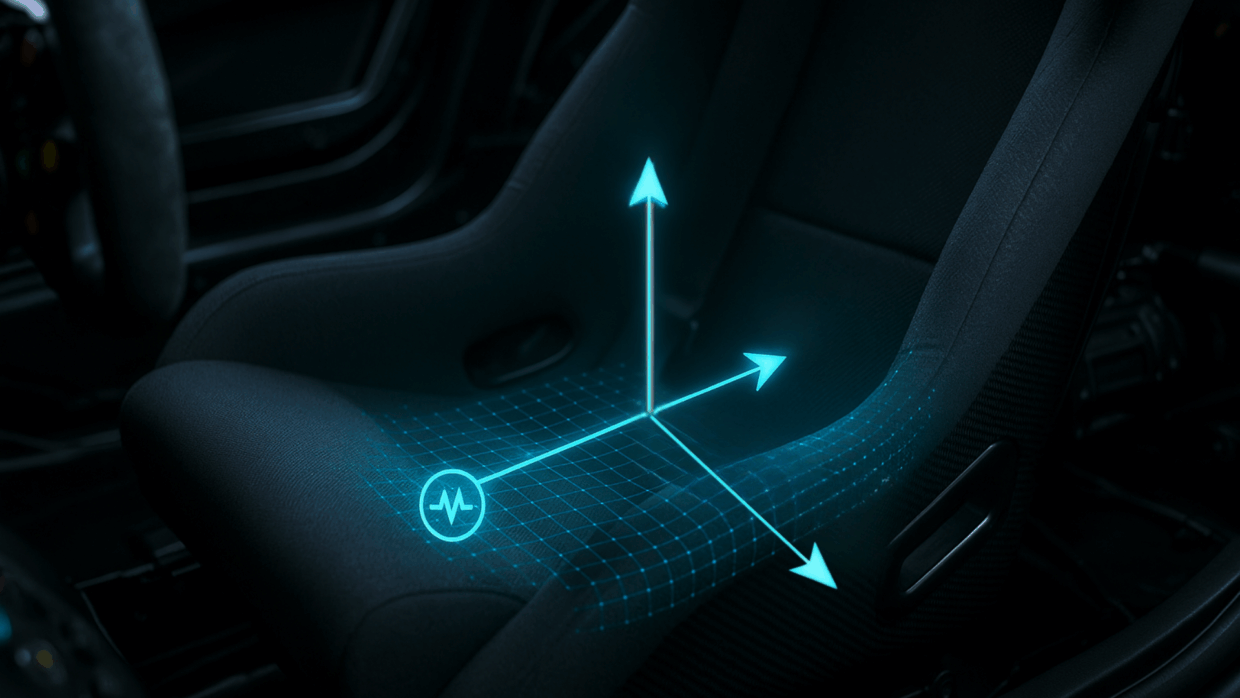

MEMS (MicroElectroMechanical Systems) have become indispensable in modern automotive engineering. These sensors, often smaller than a fingernail, can precisely measure fundamental physical quantities: accelerations, vibrations, orientations, pressures.

In racing cars, their use is widespread and varied. For example, triaxial accelerometers are placed under the driver’s seat to record longitudinal, lateral, and vertical accelerations experienced by the body during cornering, braking, or impacts. These measurements correlate the driver’s perception with the actual loads acting on the chassis.

Other MEMS are mounted on suspensions or wishbones, capturing local vibrations and load transfers, allowing engineers to characterize chassis stiffness or detect phenomena such as porpoising. Some systems even integrate dynamic pressure sensors into the seat itself to track the pilot’s body load distribution, giving indirect but extremely precise insight into physiological responses to track conditions.

The key takeaway: MEMS provide an absolute reference frame. They represent the starting point of vehicle dynamics in the real world. When simulation studios claim to use real-world data to model their cars, these measurements are a core part of the process. In other words, the Force Feedback signals we receive at the wheel are already derived from these references. The real challenge is not whether the physics are correct, but rather how our brain perceives and interprets this signal through the visual interface we configure in the simulation.

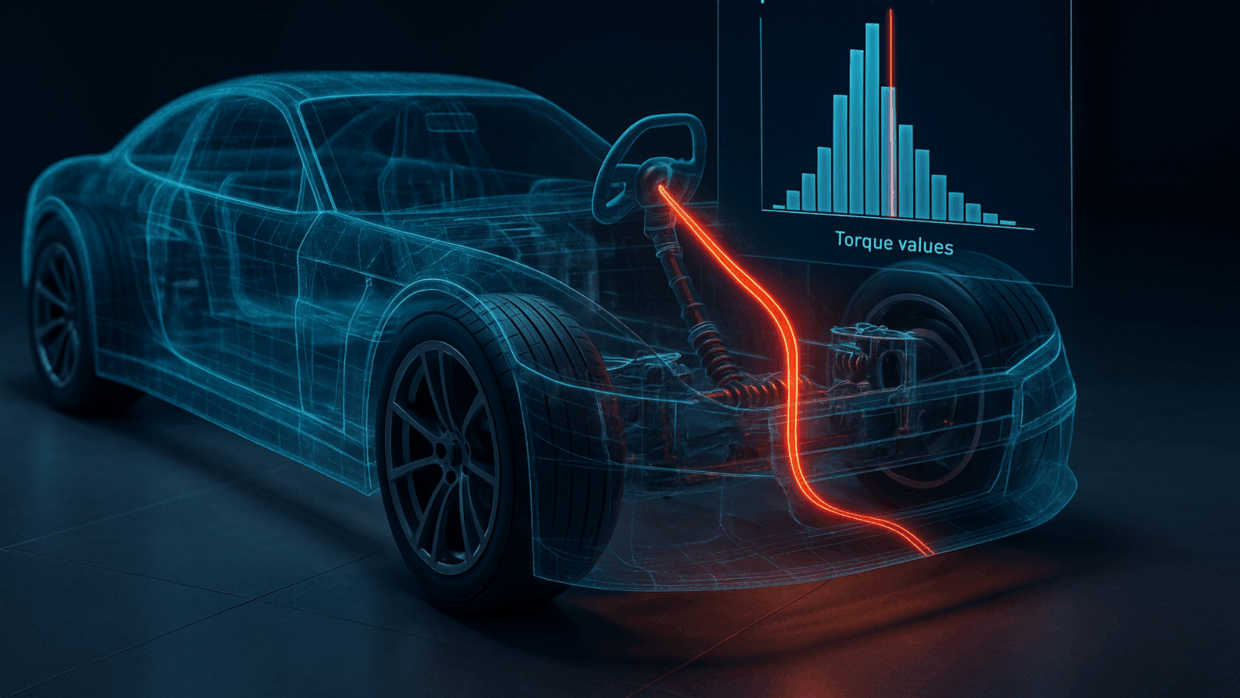

p99 Torque: A Statistical Compass

To move beyond subjective impressions, we introduced a robust statistical metric: p99 torque. This is defined as the 99th percentile of steering torque values over a reference lap.

The benefit of this approach is twofold:

it filters out rare extreme values caused by events such as curb strikes or sudden slides,

while capturing the upper limit of representative forces encountered in normal driving conditions.

Where an average would flatten out significant peaks, the p99 highlights the true upper edge of physical stress.

Our initial tests across multiple vehicles—GT3s, prototypes, Hypercars—revealed a crucial finding: p99 is remarkably stable under constant conditions. Regardless of track, as long as setup and environment remain fixed, p99 varies very little from lap to lap.

This stability makes p99 a true “fingerprint” of a car in simulation. For example, a Ferrari 296 LMGT3 shows a p99 around 50 Nm, while a Mercedes AMG GT3 comes in closer to 24 Nm. These values reflect real-world design differences and reliably capture their distinct dynamic identities.

Thus, p99 becomes a trustworthy reference—allowing us to compare cars, analyze data, and most importantly, separate raw physics from subjective perception.

When FOV Brings You Closer to—or Further From—Physics

Our experiments show that Field of View (FOV) plays a fundamental role in Force Feedback interpretation. By changing only this parameter—from, say, 30° to 80°—the p99 remains identical, proving the physics engine outputs the same signal, yet the driver’s perception changes drastically.

With an overly wide FOV, the car feels slower, corners appear flatter, and the wheel feels “flat” and lacking in detail. With an overly narrow FOV, speed is exaggerated, weight transfers feel more violent, and the wheel becomes “nervous” or even brutal.

But FOV is not simply a zoom in or out: it is a vector of distance from the reference point defined by the physics engine. Each degree of miscalibration moves you further away from the MEMS data reference. The greater the gap, the stronger the desynchronization between sight and touch, and the greater the mismatch.

In fact, FOV can push you infinitely far from the “ideal” position, creating a completely distorted reading of the physical signal.

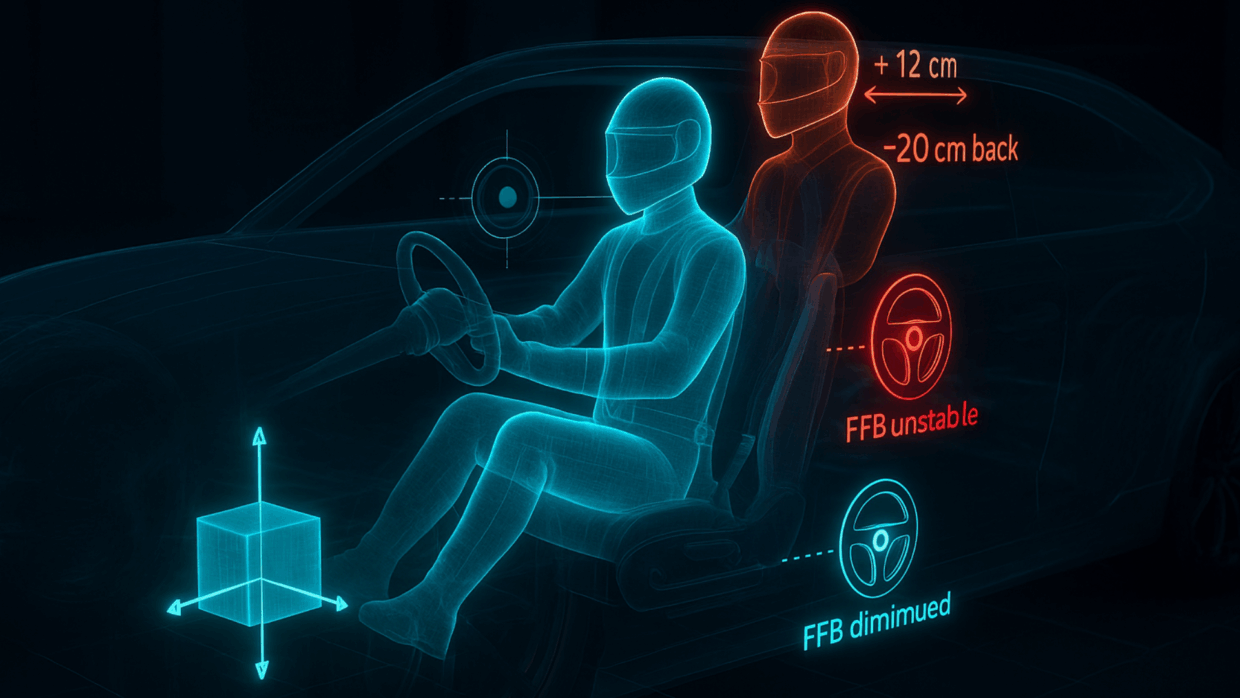

On top of this, the virtual driver’s position in the cockpit (forward/backward, higher/lower) acts as a fine calibration. Even with a geometrically correct FOV, a camera that is too low or too far back distorts the perception of load transfers and alters the interpretation of FFB. Together, FOV and cockpit position must be treated as one system: the first defines the global geometry, the second delivers fine adjustment.

Virtual Driver Position: The Hidden Variable

If FOV is the primary adjustment of the “sensor receiver,” then the cockpit camera position is its fine calibration. In reality, MEMS are installed in specific spots on the chassis—typically under the driver’s seat. Moving a sensor a few centimeters up or back would yield slightly different readings, since vibrations and accelerations vary across the structure.

In simulation, we cannot move the virtual sensor, but we do move our virtual eyes. The physics engine keeps outputting the same raw signal, but our perception changes because the visual frame of reference no longer matches the physical one.

Many simracers report that even slight adjustments of cockpit height or seating depth significantly change how the wheel feels. This was exactly Florent’s experience: initially skeptical, he became convinced after systematic testing. By moving his FOV and cockpit position, he uncovered drastically different behaviors—sometimes making certain corners impossible to take with the same setup. His testimony illustrates clearly that this is not placebo: perception is truly altered by visual adjustment.

Testimony: Florent and the Rediscovery of FFB

This testimony reinforces our measurements: p99 remains constant, but the driver’s lived experience changes depending on alignment between vision and force perception.

Conclusion: Toward a Standardization of Settings

Our work demonstrates that p99 torque is a reliable, stable measure of simulated physics. Yet the driver’s feel can vary dramatically depending on FOV and cockpit position. This discrepancy is explained by a mismatch between the physical reference (MEMS) and visual perception, creating sensory incoherence.

Rather than endless debates about the “best FFB gain,” a structured method seems more productive:

Calibrate FOV geometrically based on eye-to-screen distance.

Set cockpit camera realistically to match a plausible driving position.

Only then adjust FFB gain (P99) to scale the raw signal to your hardware.

This ensures the signal you work with is aligned to physics, not distorted by a mismatched reference frame.

Leave a Comment